Air entraining admixture

Area of Applications :

To produce air entrained concrete for increased durability and resistance to damage by frost and deicing salts. Typical applications include concrete roads and bridge decks, airport runways and taxiways and other extensive areas of concrete exposed to potential frost damage.

To improve cohesion and workability of concrete mixes where poorly graded aggregates must be used and bleeding, segregation or sand runs occur.

As part of a combined admixture system for the production of ready mixed retarded mortar.

Benefits of Armix AE :

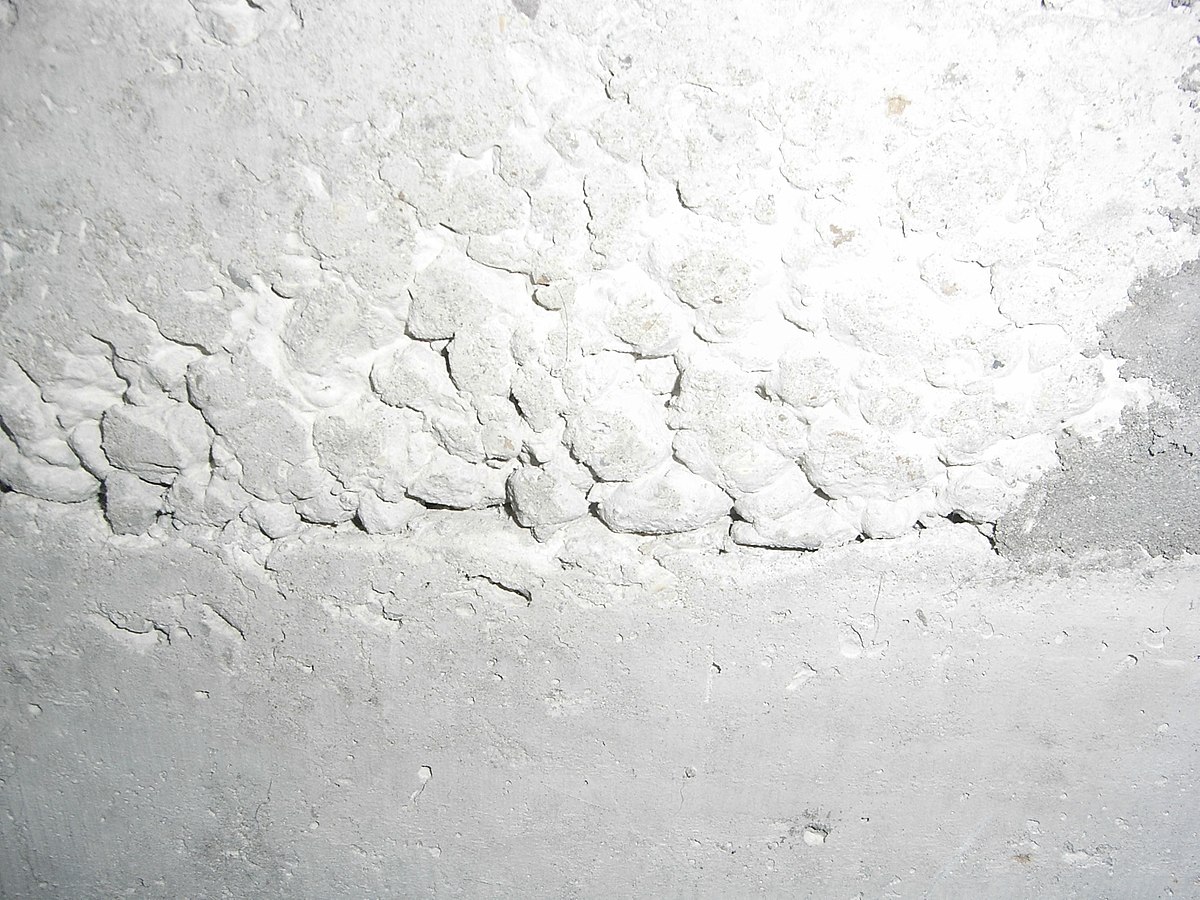

Air entrainment increases the resistance of concrete to attack by frost and de-icing salts, reducing problems of surface scaling and concrete failure.

Entrained air bubbles assist in the formation of a stable cohesive mix, reducing segregation and bleeding.

Air entrainment improves workability and helps produce a dense, uniform, close textured surface free from gravel nests and sand runs, so further enhancing durability.

Excellent air bubble stability allows use with a wide range of aggregate qualities and mix conditions.